The aim of this project was to create reliefs by curing silicone (or other curable materials) in a sub woofer. Two methods were tested: a Chladni plate using sand and simply placing a petri dish with liquid on the speaker cone. As the petri dish was able to generate smaller features, this method was selected.

The Idea

What if you could create organic-looking reliefs in silicone or other curable materials without having to create a mould or use additive or subtractive manufacturing? The idea behind this project is that ice can freeze in all sorts of shapes, including waves, so why not silicone? Possible applications include moisture-wicking surfaces, for example in prosthetics where there’s an interface between prosthetic and skin, or anti-slip surfaces. Another interesting material to explore would be polymers where a particular alignment of the polymer chains is desired. Using acoustics to manipulate fluids is an established field, but these studies usually focus on the micro scale, relying on piezoelectric actuation for flow generation (Yeo and Friend, 2013).

Setup

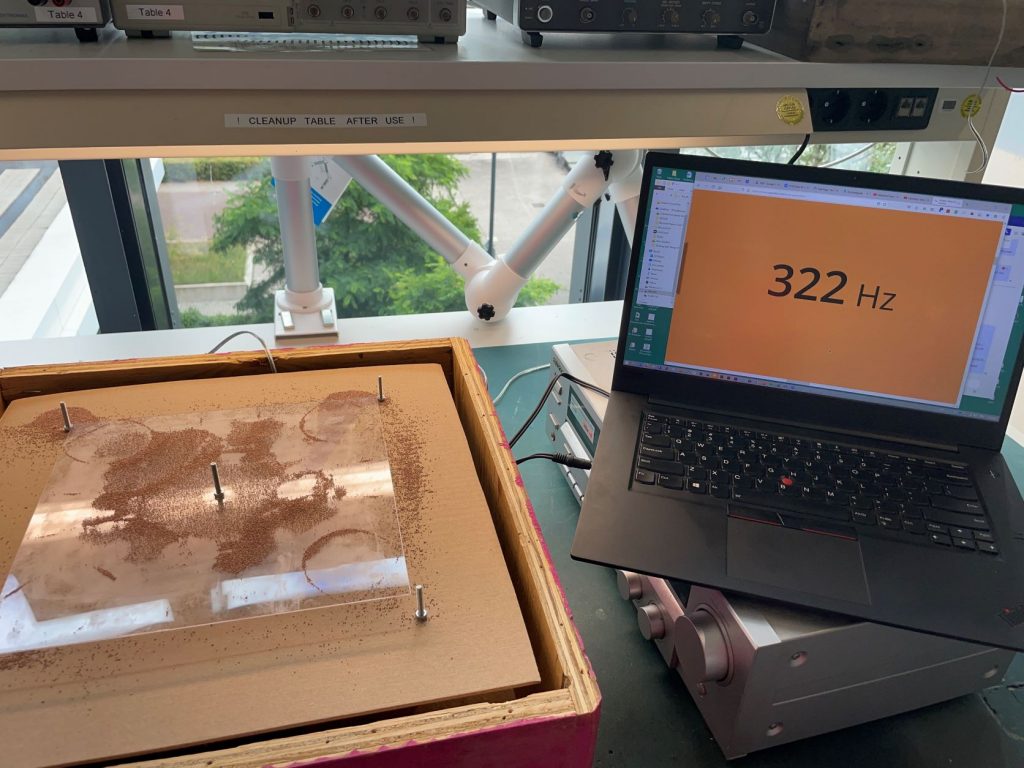

The first step was to build a Chladni plate. For this, one of the d.search staff was kind enough to make his sub woofer and driver available for a few days. The sub woofer was equipped with a cover (to prevent sand from falling in), a cap fastened to the cone, and a plate (1mm vivak) attached to the cap. Sand was then poured onto the plate, which displayed patterns at certain frequencies (the resonant frequencies of the plate). The patterns were best visible at lower frequencies, but unfortunately these tend to be quite large. This is explained by Chladni’s law:

(m and n are number of nodes, C and p are constants that differ per plate) (“Chladni’s Law,” 2022)

This formula holds for circular flat plates, but it also explains why the observed patterns lacked the high density of lines I was looking for. At lower frequencies, m and n will also be lower, which means fewer nodes, and thus fewer lines in the patterns. I could have realised more intricate patterns at higher frequencies, but this required a higher amplitude (louder sound), which would be impractical.

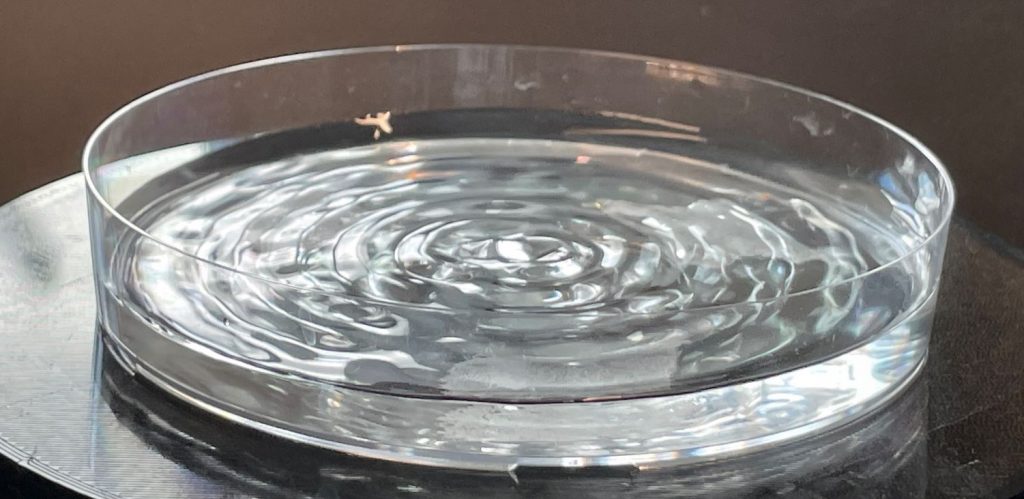

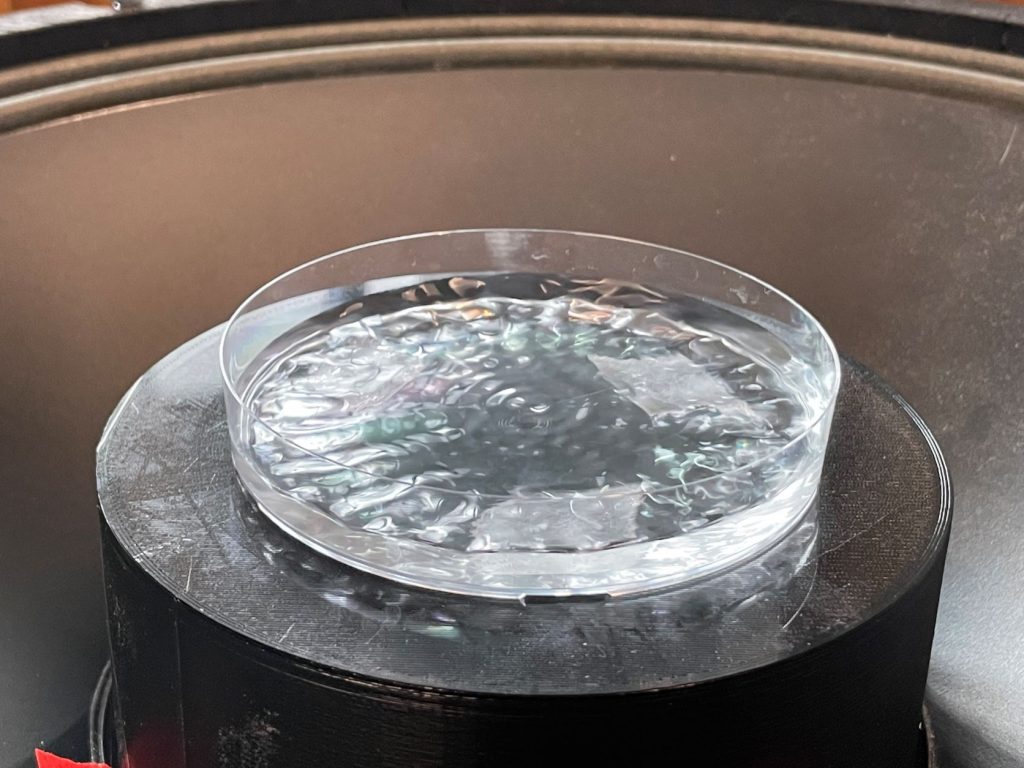

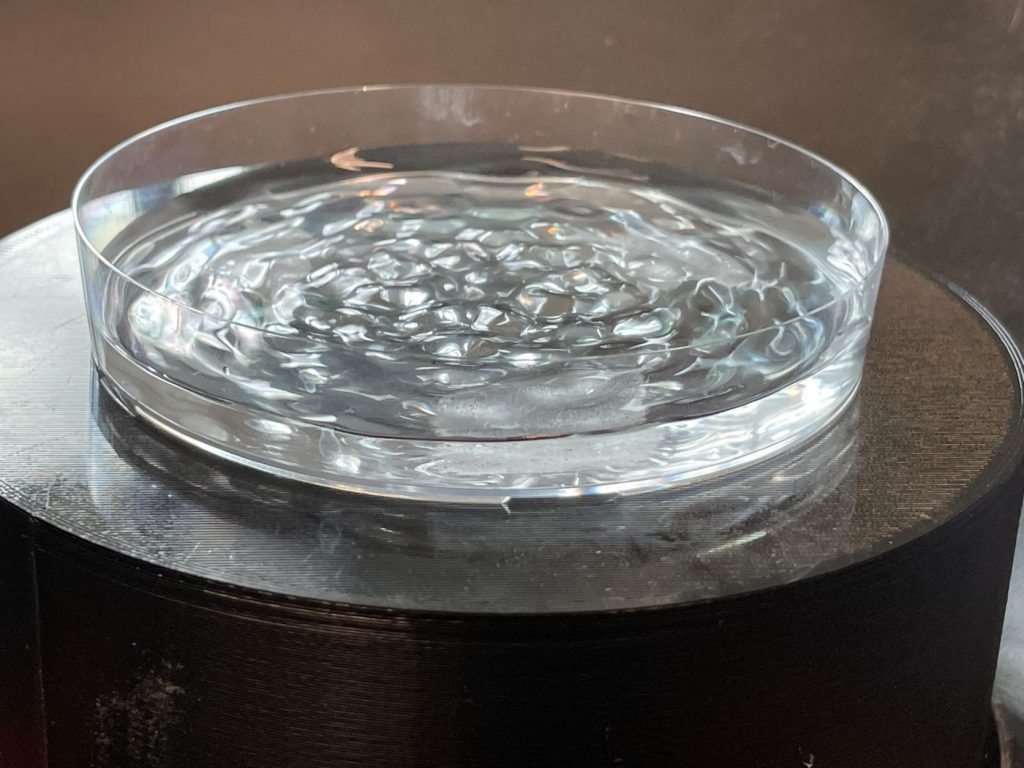

I thus moved to actuating a fluid (water) in a petri dish directly on the speaker cone. This produced the more intricate patterns I was looking for, and gave me some nice photos and videos in the process. At certain frequencies, the water would display patterns, some of which featured standing waves, so the pattern appeared to be frozen in time. These patterns are probably most suitable to recreate in silicone.

The next step was to pour two-part silicone in the petri dish, find the frequencies that produce standing waves (this depends on various factors, including viscosity of the material), and let the audio signal play for the duration of the curing time.

Unfortunately, the high viscosity of the silicone also meant that it was not possible to generate waves. However, there should be some possibilities with much less viscous materials, such as photocurable resins.

References

Chladni’s law. (2022). In Wikipedia. https://en.wikipedia.org/w/index.php?title=Chladni%27s_law&oldid=1087502742

Yeo, L. Y., & Friend, J. R. (2014). Surface acoustic wave microfluidics. Annu. Rev. Fluid Mech, 46(1), 379-406.